News & Events

热门关键字:食品净化车间 医药洁净车间 低温车间 洁净室 无尘洁净室

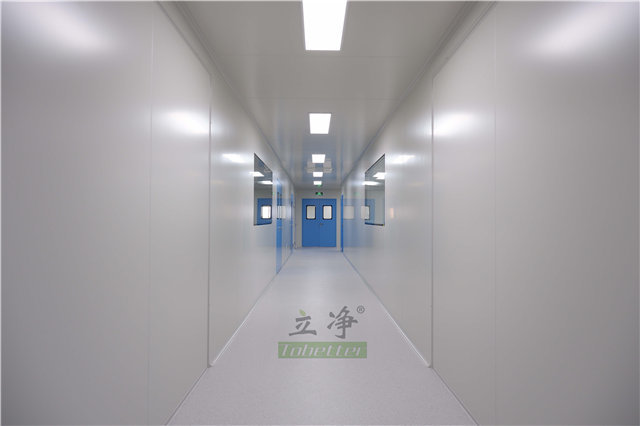

Cleanroom design of material purification

Published on.

2022-08-24 14:26

The material purification of clean room design is mainly for the clean treatment of raw materials, semi-finished products, tools and equipment during their transportation and transmission. The entrance and exit of materials and personnel should be set separately.

After the materials are cleaned in the clean preparation room, how should they continue to be transported? Mainly depends on the requirements of the product production process, which directly affects the location of the clean preparation room selection. Materials should generally go through the airlock room into the clean room (area), the airlock room is often adjacent to the clean room (area) or in the clean area, so its indoor air pressure should be maintained with the clean production area between a reasonable pressure difference. Make clean air flow from the clean production area to the preparation room.

If the workshop production flow is strong or in order to prevent different levels of clean room (area) between each other or cross-contamination or production process requirements to prevent unnecessary cross-contamination, materials in the clean room in accordance with the provisions of the process flow through the transfer window or other devices in order to pass.

In order to adapt to the products, intermediate products in the process of material transfer between different situations, the use of different types of transfer windows. Generally two flat door box-type transfer window, often two doors into a mechanical interlock switch, that is, a door in the closed state, the other door to open; also some simplified for non-interlocking, relying on the use of their own management; in the pharmaceutical production plant using the box set up inside the UV lamp for the transmission of sterilization; in the case of frequent switching or open for a long time, some also in the box body The air curtain with high efficiency filter is set.

Sterilization equipment is often used in aseptic clean rooms to pass materials, most of this equipment is electric or steam heating, one end of the equipment from the sterile area to open the door, input materials after a period of heating sterilization and then open the other end of the door from the sterile room to take out the materials.

In addition, the flow of work, some need to open holes in the clean Zai partition wall, in order to constantly through the wall output products, so the hole that becomes a weak link of indoor purification. The general treatment method is to increase the indoor positive pressure, or set up the air curtain device above the hole when the river; when transporting small items, such as the sterile room of the dispensing vials, you can also ensure that the indoor positive pressure in the case of the conveyor belt are located on both sides of the hole, the hole set up ultraviolet light.

In a word, the design of the zone of material purification should be organically combined with the process flow, the arrangement of purification air conditioning system and the material transfer characteristics. At the same time, the route should be simple and clear; avoid round trip, too many twists and turns and cross; space as open and smooth as possible, and should be considered together with safety entrances and exits and visiting routes.

Related News

2022-06-23