Purification project

热门关键字:食品净化车间 医药洁净车间 低温车间 洁净室 无尘洁净室

Circuit board electronic purification project - Kunshan Dayang

Category:

Project Description

Kunshan Dayang Cleanroom Decoration

Project Name:Kunshan Dayang Circuit Board Co.

Project content:10,000 class purification project

Industry Category:Circuit board electronic purification project

■Introduction of Kunshan Dayang

The clean room of Kunshan Dayang Circuit Board Co., Ltd. is constructed by our company Shanghai Lijing, with clean grades of 100,000 and 10,000. The area of color plate is about 7000 square meters, the purification area is 2800 square meters, ISO7 class clean room (static, temperature 20℃-24℃, humidity≤55%), ISO8 class clean room (static, temperature 20℃-24℃, humidity≤55%) the remaining area adopts comfort air conditioning. Workshop lighting is anti-UV lamp. The air conditioning and ventilation system uses water-cooled modular units, because the equipment needs to run 24 hours, the choice of water-cooled energy-saving and constant temperature and humidity effect is very stable.

■ Key Notes:

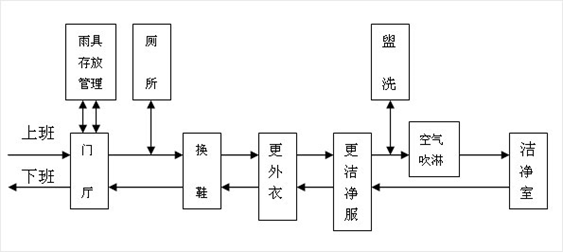

1、People flow

1-1、Personnel purification:

1-2, clean room entrance should be set up air blowing shower room. When there is no air blowing room, there should be an airlock room;

1-3, single air blowing shower room, should be set up according to the maximum class size of 30 people. Clean room personnel more than 5 people, air blowing shower room side should have a one-way bypass door;

1-4, air blowing shower room into and out of the door shall not be opened at the same time, should take chain control measures.

1-5, air cleanliness level 5 or strict than 5 vertical unidirectional flow clean room, it is appropriate to set up airlock room.

2、Logistics

2-1, clean room equipment and material entrances and exits, should be set up independently, and should be set up according to the characteristics of equipment and materials, nature, shape, etc. purification with room and the corresponding material clean facilities.

2-2, material purification with room and clean room should be set up between the airlock room or transfer window.

3、Differential static pressure

3-1, the static pressure difference between clean rooms of different levels should be greater than or equal to 5 Pa.

3-2, the static pressure difference between the clean room and the non-clean room should be greater than 5 Pa.

3-3、The static pressure difference between clean room and outdoor should be more than 10Pa.

4、According to the production requirements need to design the corresponding anti-static facilities.

5、Electronic industry clean room air cleanliness level table

| Air cleanliness level(N) | Greater than or equal to the maximum concentration limit of the required particle size(pc/m³) | |||||

| 0.1μm | 0.2μm | 0.3μm | 0.5μm | 1μm | 5μm | |

| 1 | 10 | 2 | -- | -- | -- | -- |

| 2 | 100 | 24 | 10 | 4 | -- | -- |

| 3 | 1000 | 237 | 102 | 35 | 8 | -- |

| 4 | 10000 | 2370 | 1020 | 352 | 83 | -- |

| 5 | 100000 | 23700 | 10200 | 3520 | 832 | 29 |

| 6 | 1000000 | 237000 | 102000 | 35200 | 8320 | 293 |

| 7 | -- | -- | -- | 352000 | 83200 | 29300 |

| 8 | -- | -- | -- | 3520000 | 832000 | 29300 |

| 9 | -- | -- | -- | 35200000 | 8320000 | 293000 |

Note: According to different measurement methods, the effective digits of the concentration data of each level should not exceed 3 digits.

Choose us Five advantages

Focus on food and drug, electronic industry clean room one-stop solution 18years since the establishment of a professional safety management system

18 years industry experience

1、18 years industry experience

◆ 18 years of precipitation

◆ 200 successful cases

◆ Repeat customers and word-of-mouth customers account for a high percentage

◆ Increasing number of well-known corporate clients

Construction Level 2 Qualified Enterprise

2、Construction Level 2 Qualified Enterprise

◆ Decoration Level 2 Qualification, Mechanical and Electrical Level 3 Qualification, General Contractor of Construction Level 3 Qualification

◆ Have a safety production license

◆ Self-built professional safety management system

◆ Zero major safety accidents since 18 years

3、60 technicians of all kinds

60 technicians of all kinds

◆ We can design and build high level GMP workshop class A and class 1 clean room

◆ Tailor-made design solutions

◆ Project design are strictly implement GB50073-2013\GB 50473-2008\GB50457- 2008 and other national standard clean specification and the United States federal 209E standard

Third party acceptance test verification

4、Third party acceptance test verification

◆ Self-provided full set of testing instruments, first self-test after third-party testing

◆ The project construction strictly implements national GMP, US FDA and EU Euro GMP and other domestic international standards.

Customer Focused

5、Customer Focused

◆ Complete standardized process to ensure the construction period and quality

◆ One year after the warranty period, take the initiative to visit 2 times and 1 time at home

◆ We are convinced that our work is only valuable if the users are satisfied.