Purification project

热门关键字:食品净化车间 医药洁净车间 低温车间 洁净室 无尘洁净室

Fresh food processing clean room-Papa John

Category:

Project Description

Papa John'sFresh food processing clean roomRenovation work

Project Name:Shanghai Papa John Restaurant Management Co.

Project Location:Shanghai

Industry Category:Fresh food processing purification project

■About Papa John

PaPa John's is one of the world's top three pizza giants, headquartered in the United States and founded by John & middot; Snyder in 1984 as the world's first Papa John's pizza restaurant. It has more than 4,000 outlets worldwide. Since its official entry into China in October 2003, PaPa John's has opened a hundred restaurants in East China.

Papa John's since1984,When I opened the world's first John's restaurant in 1984, my goal was to make better pizza, pizza that my family would love. To that end, I insisted on using fresh, homemade, traditional dough, freshly picked and filled special tomato sauce, a selection of high-quality cheeses and meats, and fresh vegetables. These are the standards of product quality that I set for Bar John's in 1984 and that we continue to uphold today.

■ Key Notes:

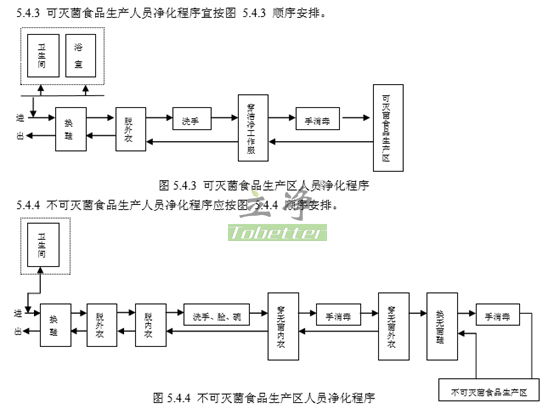

1、Human abortion

1-1、Personnel purification flow chart:

1-2, the food industry has clear regulations on the movement of personnel and materials, no cross flow, material flow needs to set up a special material transfer port or transfer door; personnel flow needs to take a special personnel channel.

2, according to the production process and health, quality requirements, divided into clean levels, specific levels and requirements:

Food industry clean room air cleanliness class table

| Class of clean room | Maximum allowable number of suspended particles/m³ | |||

| Static | Dynamic | |||

| ≥0.5μm | ≥5.0μm | ≥0.5μm | ≥5.0μm | |

| ⅠLevel | 3520 | 29 | 35200 | 293 |

| ⅡLevel | 352000 | 2930 | 3520000 | 29300 |

| ⅢLevel | 3520000 | 29300 | No provision | No provision |

| ⅣLevel | 35200000 | 293000 | No provision | No provision |

3. For liquid processing workshop, special attention should be paid to the stain residue caused by flushing in the installation of aluminum profiles, which produces moldy odor in summer and requires special treatment.

4, personnel hand washing faucet shall be non-manual (induction, foot or hand lining type), the production plant import necessary to set up work boots disinfection pool.

Choose us Five advantages

Focus on food and drug, electronic industry clean room one-stop solution 18years since the establishment of a professional safety management system

18 years industry experience

1、18 years industry experience

◆ 18 years of precipitation

◆ 200 successful cases

◆ Repeat customers and word-of-mouth customers account for a high percentage

◆ Increasing number of well-known corporate clients

Construction Level 2 Qualified Enterprise

2、Construction Level 2 Qualified Enterprise

◆ Decoration Level 2 Qualification, Mechanical and Electrical Level 3 Qualification, General Contractor of Construction Level 3 Qualification

◆ Have a safety production license

◆ Self-built professional safety management system

◆ Zero major safety accidents since 18 years

3、60 technicians of all kinds

60 technicians of all kinds

◆ We can design and build high level GMP workshop class A and class 1 clean room

◆ Tailor-made design solutions

◆ Project design are strictly implement GB50073-2013\GB 50473-2008\GB50457- 2008 and other national standard clean specification and the United States federal 209E standard

Third party acceptance test verification

4、Third party acceptance test verification

◆ Self-provided full set of testing instruments, first self-test after third-party testing

◆ The project construction strictly implements national GMP, US FDA and EU Euro GMP and other domestic international standards.

Customer Focused

5、Customer Focused

◆ Complete standardized process to ensure the construction period and quality

◆ One year after the warranty period, take the initiative to visit 2 times and 1 time at home

◆ We are convinced that our work is only valuable if the users are satisfied.