Purification project

热门关键字:食品净化车间 医药洁净车间 低温车间 洁净室 无尘洁净室

Purification project installation-Shuguang

Category:

Project Description

ShuguangCleanroomRenovation work

Project Name:Zhejiang Shuguang Technology Co.

Project content:10,000 class purification project

Industry Category:Medical equipment purification project

■Introduction of Aurora

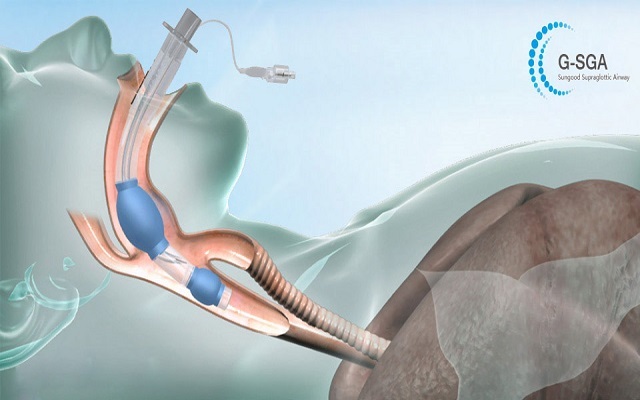

Zhejiang Shuguang Technology Co., Ltd. is a high-tech enterprise under Shuguang Holding Group. Built " Zhejiang University — — dawning technology biomedical materials research and development center ", is the first batch of Hangzhou City to establish " academician workstation " enterprise. The main production of laryngeal mask and other respiratory anesthesia products, gastrointestinal nutrition tube class, urinary series, the third category of biodegradable absorption implantable biological materials and other medical supplies. Has passed ISO13485, CE, FDA and other certifications.

The purification project constructed by Shanghai LJ reaches 10,000 and 100,000 levels, with a clean workshop area of 7,000 square meters, temperature of 18-26 degrees, humidity of 55±10%. The air conditioning of the cleanroom adopts chilled water mainframe cooling plus steam heating system, constant temperature and humidity control, and the control adopts Siemens intelligent control system. It has successfully passed the third-party authoritative clean room test and meets the requirements of GMP workshop certification.

■ The importance of cleanroom technology for industrial production

The importance of clean room technology for industrial production, with the rapid development of economic and social, especially in microelectronics, biotechnology, high precision machine processing as the representative of the scientific test and high-tech production process, the enterprise product finishing precision, miniaturization, high purity, high quality and high reliability put forward a higher standard. Indoor environment not only affects the physical and mental health and comfort of the practitioners in production and processing activities, but also affects the production efficiency, product quality, and even the processing can be carried out in the primary question.

The clean room concludes that the impact of the space environment on the processing process is as follows:

(1) Significant impact on the processing

Indoor environment is one of the primary conditions that control industrial production, especially high-tech production can not be carried out. For example, in the microelectronics industry, the chip production process, the control of microscopic particles to meet the standard molecular level, otherwise the production can not be carried out, or production and processing of residual products; in the production environment of antimicrobial agents, if there are some microbial strains, the production can not be carried out properly.

(2) Impact on productivity

The influence of indoor environment on production efficiency is reflected in the following 2 aspects: first, an excellent environment can not only guarantee the physical and mental health and attendance of production and processing personnel, but also improve their working mood and enthusiasm; on the other hand, an excellent environment can ensure the smooth development of production and improve the product qualification rate.

(3) Affect the quality of products

Indoor production environment is one of the main factors affecting the quality of products. For example, light-sensitive film, electronic devices, experimental reagents, precision electronic instruments and micro-motors and other products, if contaminated by dust, will reduce product quality and even scrap; in the food processing industry, the presence of micro-organisms will shorten the shelf life and reduce product quality.

(4) Causes environmental pollution

As we all know, environmental pollution is mainly caused by industrial pollution. Among them, air pollution and water pollution on the one hand cause harm to people's physical and mental health, on the other hand, it also endangers the processing and product quality.

The importance of clean room technology for industrial production; therefore, in order to reduce the impact of indoor air pollution on the process, it is necessary to improve or solve the problem of indoor air pollution through clean technology. It is fully certain that in a general workshop you have to control the concentration of suspended particles in the entire micro-indoor environment so that it reaches the standard production process standard clean level is completely impossible. Only by building a clean room, adopting a closed space structure, rationalizing the airflow organization and rationalizing the pressure difference, can the micro-environment reach the required air cleanliness level and meet the production requirements.

Choose us Five advantages

Focus on food and drug, electronic industry clean room one-stop solution 18years since the establishment of a professional safety management system

18 years industry experience

1、18 years industry experience

◆ 18 years of precipitation

◆ 200 successful cases

◆ Repeat customers and word-of-mouth customers account for a high percentage

◆ Increasing number of well-known corporate clients

Construction Level 2 Qualified Enterprise

2、Construction Level 2 Qualified Enterprise

◆ Decoration Level 2 Qualification, Mechanical and Electrical Level 3 Qualification, General Contractor of Construction Level 3 Qualification

◆ Have a safety production license

◆ Self-built professional safety management system

◆ Zero major safety accidents since 18 years

3、60 technicians of all kinds

60 technicians of all kinds

◆ We can design and build high level GMP workshop class A and class 1 clean room

◆ Tailor-made design solutions

◆ Project design are strictly implement GB50073-2013\GB 50473-2008\GB50457- 2008 and other national standard clean specification and the United States federal 209E standard

Third party acceptance test verification

4、Third party acceptance test verification

◆ Self-provided full set of testing instruments, first self-test after third-party testing

◆ The project construction strictly implements national GMP, US FDA and EU Euro GMP and other domestic international standards.

Customer Focused

5、Customer Focused

◆ Complete standardized process to ensure the construction period and quality

◆ One year after the warranty period, take the initiative to visit 2 times and 1 time at home

◆ We are convinced that our work is only valuable if the users are satisfied.