Purification project

热门关键字:食品净化车间 医药洁净车间 低温车间 洁净室 无尘洁净室

Electricity purification project-Debonair Lighting

Category:

Project Description

DebonairPurification projectDesign and Installation

Project Name:Hengdian Group Debonair Lighting Co.

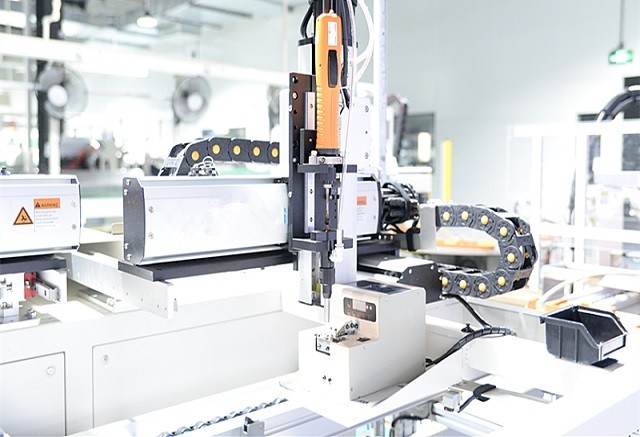

Project content:100,000 class purification project

Industry Category:Precision Electronics

■About Debonair

Ltd. (hereinafter referred to as the company) is a holding subsidiary of Hengdian Group, located in Hengdian Town, Dongyang City, Zhejiang Province, the hometown of Chinese film and television—— established at the end of 1996, mainly engaged in the research and development, manufacturing and domestic and international sales of five series of products: light source, indoor lighting, professional lighting, lighting control and engineering plastics, and supporting In recent years, we have gradually involved in the field of intelligent lighting. The company is a national high-tech enterprise, a national intellectual property demonstration enterprise and a China export quality and safety demonstration enterprise, and has been recognized as an enterprise technology center in Zhejiang Province, approved as a provincial enterprise research institute, and set up a provincial academician expert workstation and a provincial postdoctoral workstation.

■ Engineering construction matters:

1. Partition wall

(1) The material of the partition wall is: 50mmt handmade rock wool color steel plate, the thickness of the color steel plate is 0.476mm.

(2) The building envelope and interior decoration of the clean plant shall take reliable air tightness treatment. The gap between the board and the board is 2-3mm, and must be played with neutral environmental protection silica gel.

(3) The surface of the wall in the clean room is flat, smooth, dust-free, avoiding glare, and easy to dust.

2. Ceiling

The material of the ceiling is: 50mmt handmade rock wool color steel plate, the thickness of the color steel plate is 0.476mm, the height of the ceiling is 4.5m.

3. Doors and windows

(1) The location of the doors and windows should be opened on the whole board, except for those indicated.

(2) Doors and windows are made of aluminum alloy, and doors make colorful steel plate doors; windows use transparent glass.

(3) The installation height of the viewport depends on the actual situation on site.

(4) All doors and windows ensure that specifications and quantities are carefully checked before ordering.

4. Other:

4.1. Except as indicated in the drawings, the rest are in accordance with the requirements of "Clean Room Construction and Acceptance Specification" GB50591-2010.

4.2. When installing pipeline, there are more pre-buried parts and openings, the color steel plate installation should cooperate with HVAC, weak electricity and other professional construction and installation personnel, and ensure the correct position and size of pre-buried parts and openings as required by relevant professional drawings to ensure the comprehensive quality of the project.

4.3. During the installation of the color steel plate, the maintenance channel needs to be set up to facilitate the relevant professional maintenance work.

Choose us Five advantages

Focus on food and drug, electronic industry clean room one-stop solution 18years since the establishment of a professional safety management system

18 years industry experience

1、18 years industry experience

◆ 18 years of precipitation

◆ 200 successful cases

◆ Repeat customers and word-of-mouth customers account for a high percentage

◆ Increasing number of well-known corporate clients

Construction Level 2 Qualified Enterprise

2、Construction Level 2 Qualified Enterprise

◆ Decoration Level 2 Qualification, Mechanical and Electrical Level 3 Qualification, General Contractor of Construction Level 3 Qualification

◆ Have a safety production license

◆ Self-built professional safety management system

◆ Zero major safety accidents since 18 years

3、60 technicians of all kinds

60 technicians of all kinds

◆ We can design and build high level GMP workshop class A and class 1 clean room

◆ Tailor-made design solutions

◆ Project design are strictly implement GB50073-2013\GB 50473-2008\GB50457- 2008 and other national standard clean specification and the United States federal 209E standard

Third party acceptance test verification

4、Third party acceptance test verification

◆ Self-provided full set of testing instruments, first self-test after third-party testing

◆ The project construction strictly implements national GMP, US FDA and EU Euro GMP and other domestic international standards.

Customer Focused

5、Customer Focused

◆ Complete standardized process to ensure the construction period and quality

◆ One year after the warranty period, take the initiative to visit 2 times and 1 time at home

◆ We are convinced that our work is only valuable if the users are satisfied.